Due to the vastly different operating conditions and operational health and safety concerns found across the Australian mining industry, each mine site has developed a set of specifications governing light vehicles operating onsite. These vehicles, known as mine spec vehicles, have to comply with specifications tailored to each mine’s safety and optional equipment requirements.

Keeping track of these requirements can be a complex and time-consuming task for contractors and companies that work within the mines. To make it easier to understand, let’s take a look at the requirements for mine spec light vehicles.

Each mining company in Queensland has its own set of vehicle safety and compliance standards. These requirements come from both state government as well as from mine owners themselves, all of whom are regularly reviewing and updating the industry standards.

Specifications cover all aspects of the vehicle’s safety, function, and performance while on mining property. But it’s important to note that there’s no standard ‘one-size-fits-all’ when it comes to vehicle modifications and accessory upgrades for every mine site – each site will have their own requirements for necessary accessories when it comes to mine-site health and safety.

To build the best Mine Spec vehicle, it’s important that the base vehicle is capable of operating for extended periods without breakdowns. Because of their inherent ruggedness and durability, FleetCrew uses Toyotas.

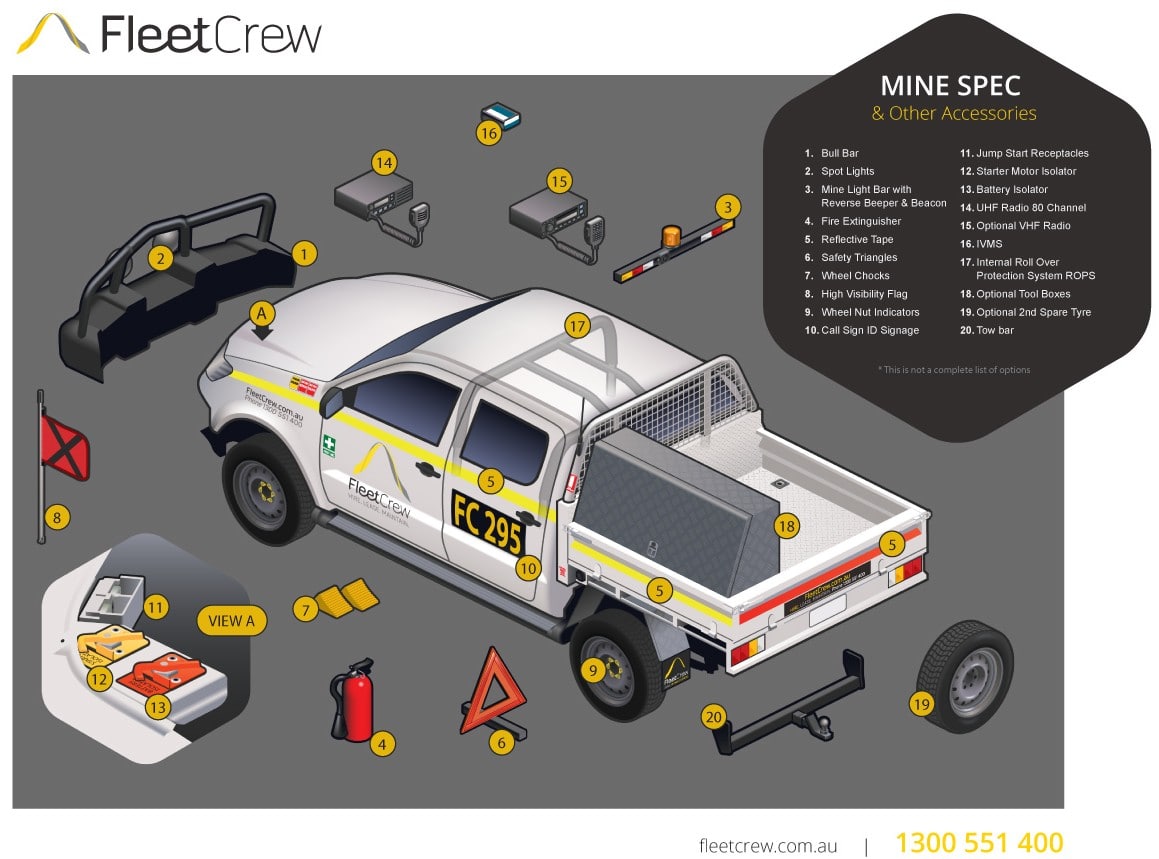

As a base for our utility vehicles, we install a Roll-Over-Protection-System (ROPS) which is integrated into the steel tray attached to the vehicle. With roll-overs an inherent risk in the mining environment, ROPS absorb the energy generated in a roll-over and are carefully engineered to integrate with the existing structural safety features of the vehicle.

We add hi-vis reflective tape to the outside of the vehicle as well as a mine light bar with reverse beeper and beacon, a unique call ID sign, and wheel nut indicators. Within the vehicle, you will find a UHF radio, an optional high visibility safety flag along with a fire extinguisher, safety triangles, and wheel chocks to provide additional peace of mind in the event of a breakdown or accident.

With these durable modifications and extras as a base, additional features can now be added based on each mine sites’ requirements. Some additional mine spec features are listed below.

View Our Mine Spec Vehicle Hire

IVMS tracks the movement, speed, and location of vehicles, as well as driver behaviour like harsh braking and seatbelt compliance of vehicles, in real time. This helps to make sure that all vehicles are compliant with site speed limits and fatigue management policies, while also providing a record of critical data in the event of an incident. IVMS units can also be fitted with a duress button as an added safety component.

A VHF (very high frequency) radio operates within a frequency range of 30 to 300 MHz. This is lower than UHF, which allows for a longer range and less interference on open areas, like mine sites. Many mine sites require pre-programed VHF radios as part of light vehicle mine specs where VHF is the primary mode of communication.

DFMS is a technology that monitors the driver’s face and behaviour for signs of fatigue or distraction. When a risk to the driver’s safety is identified, the system can issue a real time alert to the driver to correct the problem.

Data from DFMS can also be used to evaluate and improve driving habits and improve the overall safety and efficiency of a fleet of vehicles.

Safer Together is an industry-led Land Transport Working Group of Queensland Natural Gas Exploration and Production companies. The group has developed a consistent set of specifications for mine spec vehicles that operate in this industry.

The four major companies that operate under Safer Together are Santos, QGC, Arrow Energy and Origin Energy.

BMA is Australia’s largest producer and supplier of seaborne metallurgical coal and is a partnership between BHP and Mitsubishi Development. BMA operates five Bowen Basin mines (Goonyella Riverside, Broadmeadow, Peak Downs, Saraji and Caval Ridge), and owns and operates the Hay Point Coal Terminal near Mackay.

In 2025, BMA implemented stricter requirements, mandating that all light vehicles must be fitted with IVMS, a hand brake alarm and a VHF radio that is pre-programmed to site specifications prior to entering the site.

The requirements for BMA sites include:

Mount Isa Mines (MIM) is one of the world’s largest mining complexes. Operated by Glencore, it produces copper and zinc through mining and processing operations.

The requirements for MIM sites include:

Rio Tinto has operations spread across Australia. In Queensland, Gladstone is home to two Rio Tinto refineries, a smelter, and a power station. They also operate a Bauxite mine in Weipa.

While specific requirements can vary by site, standard mine spec features typically include:

If you’re still unsure about your mine spec requirements across Queensland, our team can help simplify the process. We’ll take care of vehicle selection, mine spec customisations, and ensure your vehicle meets all site compliance requirements, so you can stay focused on the work ahead.

With every vehicle backed up by a comprehensive maintenance program, FleetCrew is the preferred supplier for many companies located in Brisbane and across Queensland. So if you need a vehicle ready for any site, get in touch with FleetCrew today, and we will simplify the process from start to finish.

If you have an enquiry or would like more information then please fill in the enquiry form and we will get back to you asap during business hours.

If you are seeking a quote for a particular vehicle/s, please visit our Get A Quote page or if want to further information, please visit our FAQs page.

Providing 4WD Hire Vehicles to Australia’s Eastern States from QLD, ACT and NSW.

Monday – Friday: 7.30am – 5.00pm